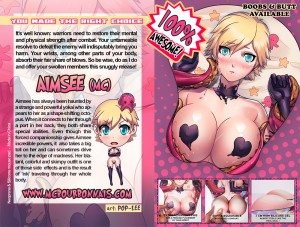

What a lovely surprise I had when I looked at my mails today! A message from an artist, Ian MacKey, or Marauder6272, who sent me this funny fanart of my OC, Aimsee! I can’t tell you how happy I am that people have been appreciating Aimsee so much since I introduced her. I had only positive comments about her and I’m looking forward to presenting you more of Aimsee in the future!

You can see more of Marauder6272’s work on his deviantart: http://marauder6272.deviantart.com/

Body filler and patience: how to make fiberglass feel and look as slick as glass

After the legs, we covered the spider’s body with fiberglass. Since the body was so big, we could use big squares of fiberglass mat instead of small pieces. However, the bigger the fiberglass mat pieces are, the more chances you have that there might be air bubbles trapped between the layers. To avoid air bubbles, you can use that metallic roller that has the shape of a paint roller without the sleeve. You roll it over the soaked fiberglass mat or cloth and then you make sure that all the air bubbles will go away. Covering the back of the spider’s body was pretty fast. Covering it’s belly was way longer. Rachnera has kind of a large textured stripped pattern on her belly that was very long to cover with fiberglass, but mostly, it was long to finish with body filler and to sand. On the next picture, you’ll see the spider’s body on its back. The part on the top is its belly.

The amber colored thing is fiberglass. It has the color of the polyester resin I use. This is how fiberglass looks like before the finishing process. The blue product is the auto body filler. Body filler exists in many colors. It takes the color of the hardener you mix with it. There are different types of auto body filler. Some very rough body filler can be used to correct the shape of a fiberglass object and to fill up the fiberglass cloth texture. Very fine body filler with a super slick texture is used at the end for the finishing sanding to fill up small holes. The last, tiny holes will be filled up with the primer coat.

As I said, before you apply body filler, you can see all the texture of the fiberglass mat or cloth. If you want fiberglass to be as slick as glass and to have its famous shiny look that we love so much, you have to cover it with body filler and to sand it a lot. You don’t want to sand fiberglass. You want to sand body filler. Fiberglass dust is what is so itchy. Whenever you need to cut or buff a part of fiberglass, that dust is THE worst part of working with fiberglass. Fiberglass dust goes everywhere: on your clothes, on your skin and it itches so much that you wish you could rip off your own skin to stop it from itching. Water won’t completely remove the dust from your skin. Hot showers make it worst. It’s recommended to take a cold shower and to use a washcloth to wash your skin when you have fiberglass dust on you. That’s why you have to wear long clothes to protect your skin when you work with fiberglass. I’ve seen guys using tape around their wrists to fix their sleeves to their gloves in order to keep fiberglass dust from entering inside their shirt. Yes, it’s that bad. As much as you can, avoid to sand or buff fiberglass. Add an even coat of body filler everywhere and sand the body filler. Since I’m not a fan of cold showers, I always wear long sleeves when I work with fiberglass. Loose clothes are also more comfortable, because they don’t touch your skin and then you feel less the fiberglass dust that went on your skin. I just bought a product called ‘liquid gloves’ that is kind of a cream that you put on your hands and arms and that is supposed to create a layer that will protect your skin from paint and fiberglass. I’ll certainly try this product during my next fiberglass projet. Also, no need to repeat that wherener you’re using polyester resin and fiberglass, you have to wear a respirator mask.

Like a glass snowball

Speaking of fiberglass dust… We were concerned about the total weight of the spider. Weight influences the transportation fees and we wanted to make sure that it would be as cheap as possible for our clients, Ninja Division and Seven Seas Entertainment. What could we possibly do to take off some weight? We could empty the spider’s body and take off the styrene. Plus, we knew that we would have to assemble the spider by ourselves before Anime Expo. So we had to figure out a way to lift that big body and install the legs. The body would better be as light as possible. We definitely had to take off the styrene inside. Yes, styrene is light, but in such a big quantity, it becomes surprisingly heavy.

I remember when we were building Lug the robot. It took 4 bundles of 12 4’ X 8’ sheets of styrene to sculpt the whole robot. Some of you may remember that picture of me where I was making snow angels in sterene. There was styrene everywhere in the workshop. 48 sheets of styrene granules that I had to clean up even months after the robot was finished. That’s why I wasn’t so enthusiastic about taking off the styrene from the spider’s body, but I knew it wouldn’t be worst than the robot.

So we cut a hole in the spider’s body with a buffer (which is a good example of a step that produces fiberglass dust… itchy, so itchy.) You can see on the next picture the stacked sheets of sterene inside the fiberglass body.

Then we took off all the styrene. It came out in bits and small pieces. It really took a while. And once again, there was styrene everywhere in the workshop, making it look like a glass snowball. Can’t remember how many garbage bags I filled up with all that styrene. Sorry, environment.

Now you can admire the empty fiberglass body. Notice how aluminium foil, that we had glued on styrene to protect it from polyester resin, stayed in the bottom of the fiberglass shell. It’s not important and doesn’t change anything since it’s hidden inside. It can stay there, it has no consequence. You have certainly also noticed a square tubing that crosses the spider’s body. It was welded on the other side to the metallic plate where the spider’s legs would be boalted. You can see it on the first picture of this part of the blog. Since that plate, located in the front part of the spider’s body, would support the whole weight of the body, we wanted to make sure that the plate wouldn’t come out from the body because of all that pressure. So we fixed the square tubing inside the body with more fiberglass. I’ll explain later how the legs were installed under the body.

Now that the body was empty, the last step was to put back the fiberglass piece that we had temporary removed. One of the only good sides of fibergalss is that it can be cut and patched as many times as you want and at the end, if you do a good job, it will not show. See how we put back the piece at its place, following the little notches we had made. We had to buff around the hole to make the surface lower in order to allow us to apply more fiberglass mat to hide the opening. If we would have only added more fiberglass mat on top of everything, we would have created a bump all around our piece that we are actually trying to hide. At the end, body filler will cover everything and you won’t be able to tell that there was once a hole there.

More body filler fun in Part 4 of my blog! And you’ll also discover how the spider’s legs were fixed to its body.

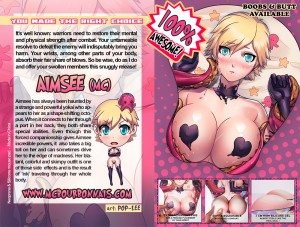

Introducing Aimsee, my original character! Discover her through some cute and sexy products like those super funny 3D mousepads. 2 versions available, boobies and booty. Your wrist will never feel the same! ;) You can order your Aimsee mousepads here.

It’s well known: warriors need to restore their mental and physical strength after combat. Your untameable resolve to defeat the enemy will indisputably bring you harm. Your wrists, among other parts of your body, absorb their fair share of blows. So be wise, do as I do and offer your swollen members this snuggly release!

Aimsee has always been haunted by a strange and powerful yokai who appears to her as a shape-shifting octopus. When it connects to her through a port in her back, they both share special abilities. Even though this forced companionship gives Aimsee incredible powers, it also takes a big toll on her and can sometimes drive her to the edge of madness. Her blatant, colorful and skimpy outfit is one of those side effects and is the result of ’ink’ traveling through her whole body.

Artwork by Pop-Lee

http://pop-lee.deviantart.com/

http://pop-leeart.tumblr.com/

You may be wondering how I started collaborating with Ninja Division – Soda Pop Miniatures and how I ended up building something as huge as Lug and Rachnera for them. Well, here’s the story.

I started collaborating with Ninja Division – Soda Pop Miniatures in 2011. They contacted me because they were interested in having me cosplaying Candy, their mascotte, and they were wondering if I knew someone who could make the costume for me.

‘I’m a costumer.’ I said. And this is how I made my very first fiberglass costume that took 6 months to do with a friend of mine who had never, just like me, worked with fiberglass before. We needed more time to build Candy’s costume than we took to build Rachnera! Yes, I know my maker friend for many years. :) But I had never thought that Candy’s costume would lead us to build such incredible things for Soda Pop in the following years.

I was supposed to wear my Candy cosplay for Gen Con that year, but it turned out to be too heavy and very uncomfortable. This costume was impossible to wear in a convention. So I called the people from Soda Pop, explained them the situation and asked them if they would let me build another costume for Gen Con. Of course, they didn’t mind! lol They were even very happy. I picked up Rin Farrah from the game Relic Knights.

It was the very first leather costume I made. It wasn’t technically perfect, but I was very proud of it.

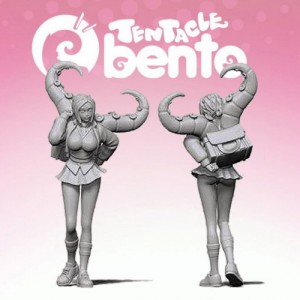

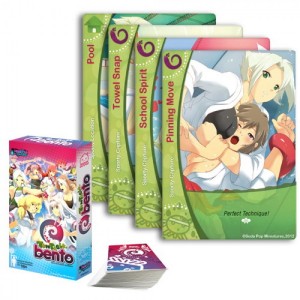

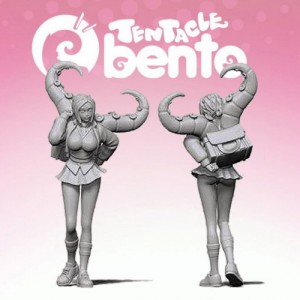

After a while, Soda Pop Miniatures offered to integrate me as a character in their games, starting with the Tentacle Bento card game. I had my own Marie-Claude character in the game, appearing on the drawings of some of the cards and having my own special edition Tentacle Bento miniature done. So cool! I still have some of these miniatures available on my store, for those who would be interested.

On the next picture, the character with short blond hair on the card is me. :) On the box, I’m the character wearing the green and white swimsuit.

At that time, I made a very cute Japanese school gym outfit and this is one of the first photoshoots I made for Soda Pop Miniatures’ Takoashi University Universe. Many of you have certainly seen those pics.

It’s the same outfit they used for the Dodgeball MC minaiture.

Then, they offered to integrate me in their game Relic Knights. My character would be part of the Cerci division. Consulting me during the process, asking for my preferences and opinion, they created a design for my character that would match the already existing costume designs of the game. My white Cerci suit was born!

Exploring the leather universe, I had decided to use that material for that costume too, making my very first leather boots by hand. It was before I met the shoemaker who helped me with the Power Girl boots. Once again, that costume wasn’t perfect, I was still experimenting a lot and didn’t know all the proper techniques to sew leather.

My friend and I had also built a set to take my Cerci suit in picture. This is the second big photoshoot that I made for Ninja Division – Soda Pop Miniatures.

I loved that wall that decorated my workshop for more than one year. I ended up using it for the photoshoot of my 1:6 scale Heroes of the North Hornet figure. Do you recognize the wall? ;)

MC Bourbonnais as Hornet from Heroes of the North

I was so sad when we destroyed that set… But I needed to build something else.

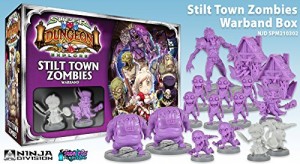

Then I was integrated in Soda Pop Miniatures’ Super Dungeon Explore game. My character was part of the Stilt Town Zombies Warband Box. That time, I was an innkeeper trying to resist to the zombies attack using her huge roller pin and iron pan.

That costume was way simpler than the leather Cerci suit, but it turned out to be more popular. The cute dress and props grabbed everybody’s attention and the complicated Cerci leather suit was quickly forgotten. You never know what people will like. I’m sometimes surprised by what is popular and what is not.

And there was also the super sexy, funny nosebleed special edition miniature!

My friend, like many little boys, I guess, had always been fantasizing about building a robot. Many will have dreams and fantasies, little will make them come true. Yes, building a big robot was one of my friend’s ideas. (One of his many, not always good ideas…) And since some of Soda Pop Miniatures characters were robots, he asked them if they would like to have a big robot at their booth eventually.

It would be such an incredible display piece! ‘Would you like to have one of your robots built for real? We could do that!’ said my friend to the Soda Pop people. ‘Who exactly is ‘we’’ I asked. ‘You and I’ he answered. ‘We have never done anything like that! What are you talking about?’ I said. And my friend replied: ‘We’ll figure it out.’ And it seems that Soda Pop was very enthusiastic about the idea of having a big robot at their booth, because they accepted to finance the project and the first thing I knew is that we were hired to build Lug, from their game Relic Knights, with the costume of Betty.

I will later write a whole blog about the making of Lug. But you already know that we finally presented Betty and Lug at Gen Con 2015. Betty was the best leather costume I had made at that time. I had met a teacher who had told me all the proper techniques to work with leather and Betty’s costume was almost perfect. It remains, in my opinion, one of my best costumes to this day.

Building Lug and rushing Betty’s costume was so much work that my friend and I almost died in the process, no joke. We were exhausted. But Lug litteraly stole the show at Gen Con 2015. Guess it was worthed.

While we were remodeling Lug and completing its final version, Ninja Division – Soda Pop Miniatures contacted us because they had another project for us. It was in April of this year. This is when we started working on Rachnera. I explain everything in my Rachnera making of blog, if you want to look at it. Rachnera wasn’t as big as Lug, but it was still very impressive and it truly was one of the main attractions at Anime Expo. Now I’m afraid of what my hands can build. I look at pictures of Lug and Rachnera and I can’t believe that we built that. I don’t know what my next project for Ninja Division – Soda Pop Miniatures will be… But one thing is for sure: if it comes from one of my friend’s suggestions again, it will be a big project.

NOTE: Before any of you ask, I’ll explain something one more time and I think I’m gonna copy/paste this at the beginning of each part of this blog. I’m not using a dust paper mask on the work in progress pics because wearing various masks irritates the skin of my face and gives me blemishes. The only fact of breathing in the humidity of my own breath in those masks makes my skin look bad. Then I can have a convention, a photoshoot or an interview and I have to wear more makeup to hide the blemishes, which isn’t good for my skin either. There are the masks for chemicals that I absolutely have to wear when I’m working with polyester resin or automotive paint. So when it comes to dust, I give my skin a break and I don’t wear a paper mask. I know it’s not the healthier choice, but most of models are usually not fiberglass technicians. I have to deal with two jobs that don’t go well together. So I make the choice, as sad as it is, not to wear paper masks to allow my skin to survive. But I do wear a mask for chemicals and vapors when I use polyester resin and automotive paint.

Sculpting styrene legs on a MDF frame guide

We had one big and one small MDF leg shape already cut. We needed 3 more of each, so we cut them. We glued styrene on each side of each MDF template and sculpted by hand each of the 8 legs. That step wasn’t too bad. It’s the finishing process, when we would later cover everything with fiberglass and try to make our 8 handmade legs look the same, that would be more complicated… Yes, we should have made molds.

We had decided at this point that we wanted some of Rachnera’s legs to hold in the air, instead of having her 8 legs touching the ground, to make her pose look more dynamic. We figured out that with the proper internal metallic structure, Rachnera could hold on her 4 bigger legs (front and back legs) and that the 4 smaller middle ones would be like a ‘decoration’ or not necessary for the structure to hold. I’ll come back later to the metallic structure, how it was integrated in the legs and how it was fixed to the spider. But first, let’s talk about fiberglass.

What’s fiberglass?

Before I say anything else, remember that you’re gonna have to wear a respirator mask and long clothes when you’ll work with fiberglass. You’ll understand why later.

When I started working with fiberglass, I didn’t know anything about it. I really learned everything from the beginning and I don’t consider myself an expert. I will share with you what I know, but my explanations will be basic. They will be the explanations of someone whose speciality job isn’t fiberglass and whose mother tongue isn’t English. Just keep that in mind and don’t hesitate to write comments, give tips and advices if you know more. Your comments are always welcome. :)

The final surface that we call ‘fiberglass’ is obtained by mixing fiberglass itself with a resin. If I understood correctly, the proper translation in English to talk about fiberglass would be fiberglass cloth (which would be the woven one) and fiberglass mat (which would be the agglomerated one. If I’m wrong, please write the correct translation in the comments.) In both cases, it looks like a shiny, white piece of fabric, it’s sold in rolls and it’s available in various thicknesses. Woven fiberglass works well when you want to cover a plain surface, like a floor or a roof. (Yes, apparently they make industrial floors and roofs in fiberglass. I didn’t know.) Agglomerated fiberglass mat is useful when you want to cover an intricate shape. You can tear small pieces of fiberglass mat and cover any type of shape by layering all these pieces of fiberglass mat all over the shape you’re covering. In any case, fiberglass has to be soaked with resin. I have always used polyester resin because it’s cheap and it catalyzes fast. However, polyester resin is a strong chemical product, it smells horrible and it’s toxic. You absolutely need to wear a respirator mask to work with polyester resin and you can’t use it in your house. You need a workshop or you have to use it outside if you can. To clean up polyester resin, if you want to use your brush more than once or if you have polyester resin on your hands, you’ll need acetone. Another product that you should never put on your skin. :S You’ll need gloves all the time. (I always use nitrile gloves instead of latex gloves because latex gloves, used to make silicone molds, can keep some silicone, like Smooth-On Rebound 25, to catalize properly. For that reason, latex gloves are prohibited in my workshop. I take no chance and use only nitrile gloves to do everything.) The polyester resin I use has a pinkish color that changes for an amber color when I mix it up with its catalysis. Without catalysis, the resin itself is a liquid. With the catalysis, it hardens. A piece made of polyester resin alone could break if you would drop it on the floor. Fiberglass mat or cloth is what gives the final piece its strenght.

There’s also shredded or chopped fiberglass. It’s applied and mixed up with resin using an air powered fiberglass spray gun or chopper gun system that throws both the chopped fiberglass and the resin at the same time. That professional equipment is used in industry to make fiberglass bathtubs, showers, boats, pools, etc. Let’s take for example a fiberglass bathtub. They will apply in the bathtub’s mold coats of gelcoat, then they will apply the chopped fiberglass and resin in the mold using the fiberglass spray gun. The part of the bathtub in which we sit will have a slick finish (the gelcoat) and the hidden part of the bathtub will have the rough texture of the chopped fiberglass. If you Google all this, you will easily find videos showing that process. My guess is that we might have used a fiberglass spraygun to cover the robot and spider. However, the price of that equipment alone would have taken part of our budget and since I don’t plan to become an official fiberglass shop, it’s not worthed investing in that. Big styrene statues or structures can also be covered with sprayable liquid plastics that can be painted. Various products exist. I didn’t know these products at that time, though. So my friend and I used what we knew and covered the robot and spider by hand, using pieces of fiberglass mat soaked in polyester resin.

Polyester resin applied on styrene makes it melt like snow in the sun. Don’t you ever sculpt styrene and apply polyester resin on your sculpture, you’ll destroy it. Styrene has to be protected from polyester resin and after many tests and searches, we found out that the best, easiest and cheapest way was to use aluminum foil. Just apply aluminum foil on your styrene structure using spray glue, make sure to put aluminum foil everywhere, cover all the styrene, and you’ll be good to go. We realized that aluminum tape works well too and is useful to cover small parts with a special shape.

On the next picture, you’ll see the spider’s body and legs that we have separately sculpted in styrene by hand. You can see the MDF template in the middle of each leg. We were at the step of covering everything with aluminum foil before starting to apply fiberglass and polyester resin. (Notice in the background the red stripe on the beige wall. That was the set we had built to shoot my Gunbuster cosplay. :) We would later paint that fake wall in grey to make another photoshoot.)

Once the whole styrene spider was covered with aluminum foil, we could start covering everything with polyester resin and fiberglass mat. That is one of the 2 worst steps. Polyester resin not only stinks, it’s also a strong chemical product that obligates anybody using it to wear a respirator mask. As I said, you also need to wear gloves. But it doesn’t take long before polyester resin makes the gloves ‘melt’ and you can feel, on the tip of your fingers, that the nitrile is reacting with the resin just before the glove rips. And then acetone is the only dangerous friend that will take off the polyester resin from your skin. No wonder why I never wear nailpolish when I’m in the middle of a big fiberglass project… You’ll need tons of gloves if you work with fiberglass. You’d better buy boxes of gloves. At the end of the project, I was always wearing 2 pairs of gloves on top of each other.

I also wear gloves when I tear pieces of agglomerated fiberglass mat. Because it itches. But it’s not the worst. Fiberglass dust is the worst. Before talking about this, let’s start with the first fiberglass step. We always prepare in advance piles of little pieces of fiberglass mat that we tear by hand. We make various sizes of pieces depending on what surface we have to cover. Then we put a piece of fiberglass mat on a flat surface and we use a brush to soak it with polyester resin. The same brush is used to apply the soaked fiberglass mat piece on the surface to be covered. You can reuse your brushes by keeping them in acetone in between the fiberglass coat applications. However, you’ll still need tons of brushes. I recommand to buy boxes of brushes too. And many gallons of acetone. On the next picture you can see the smaller spider’s legs covered with fiberglass.

As you can guess, it takes a lot of time to do things that way. It’s a very long process. You have certainly noticed the metallic structure of the smaller legs. We used 1’’ X 1’’ steel square tubing that we fixed on the extremity of the 4 small MDF legs. These tubings were welded in a particular position that would make the smaller legs hold more or less in the air. As mentioned earlier, we wanted some of the middle legs to have a different position and to hold in the air instead of touching the ground. The square tubing parts would exceed the final fiberglass legs and be used to install the spider’s legs under its body with huge boalts.

More fiberglass fun in Part 3!

It’s not what you think…

Here’s another piece of my original character, Aimsee, for those who haven’t seen the character yet. I’ll also post an official presentation that I wrote for my OC in the next days.

This piece was done a couple weeks ago and I’m pretty ashamed I haven’t posted it yet. Bokuman was super responsive and worked very fast, he even suggested me cool alternative poses for the character. Overall, I like the art a lot! It’s really funny to get my character drawn by artits with different styles. You should see more pieces from him later… if he accepts to work for me again, of course.

In the meantime, here’s a couple links to Bokuman’s work. This guy is a machine! Go browse and hit the ‘like’ button to keep him going. :)

Bokuman

Deviant Art : http://bokuman.deviantart.com/

Patreon : https://www.patreon.com/bokuman

Gumroad : https://gumroad.com/bokuman#

Facebook : https://www.facebook.com/Bokuman-Studio-143445335776733/

Instagram : https://www.instagram.com/bokuman/

Tumblr : http://bokuman.tumblr.com/

Twitter : https://twitter.com/bokuman_studio

PART 1

Once Upon A Time

It all started with Lug, Ninja Division – Soda Pop Miniatures‘ giant yellow and black fiberglass robot. For those who don’t know Lug’s long story, my friend and I have built that monster during the first half of 2015. Ninja Division needed it at their booth for Gen Con 2015, but the robot was far from completion. It still needed more sanding and had an unfinished base. But we had to deliver it for Gen Con no matter what, so the robot had been painted as it was at that moment and we had brought that temporary version to Gen Con 2015. It litteraly stole the show, but my friend and I had the feeling that it could have looked better and Ninja Division had accepted to let us bring back the robot to my workshop in Québec to remodel it and finish it properly. Fall and winter 2015 passed, I had many trips and conventions and in April 2016, my friend and I were finally almost done with the final version of the robot and its new paint. I will later write a blog about Lug’s building process. But first, let’s talk about Rachnera.

When the people from Ninja Division – Soda Pop Miniatures contacted me about a Monster Musume project, my friend and I were painting Lug. Apparently, Ninja Division wanted to collaborate on something with Seven Seas Entertainment, a company that publishes licensed mangas translated in English in the USA. They are publishing, among others, Monster Musume. Ninja Division asked me if my friend and I would be willing to build a Monster Musume cosplay that would be displayed at the booth that they would be sharing with Seven Seas Entertainment at Anime Expo, in July. The piece would be used to promote both Ninja Division’s and Seven Seas Entertainment’s products and brands.

I have to say it: I was exhausted. I couldn’t make up my mind to start another fiberglass project right after Lug. I really needed some time to recover. Building that robot was by far the most complicated thing I had ever done. I didn’t want to go through this again. The chemicals, the sanding, the itching… Not at that moment. And just like my Power Girl costume that I never thought I would make, well, it happened. Sometimes life brings you to make strange decisions.

So I had to pick up a Monster Musume character. I knew the show because I had watched the anime on Crunchyroll and I had enjoyed it a lot. Well, as a girl who has a thing for big breasts, Monster Musume had everything to please me. ;) I considered choosing Centaurea, but thinking about it twice, I quickly came to the conclusion that Rachnera would be a more impressive piece. I had to choose an exhibition piece. It had to look good from many angles, no matter from where people would take it in picture. Rachnera was bigger, taller and I had the perfect body type to bring her to life. Yes, Rachnera it would be.

Building a big huge spider

First step was to choose a scale. How big exactly should the fiberglass spider be to be proportioned with my body? If you watch a lot of animes, you may have noticed that some props scale and even costume details often change from a plan to another. Sometimes a character is holding a sword that is twice as big as him and in another episode the same sword may look smaller. It depends on the drawings, those things tend to vary. You just don’t necessary notice it while watching the anime. But if you try to cosplay one of those characters, then, you notice it. Rachnera’s body was a little like that. Her body looks bigger on some drawings, smaller on others. Since I wanted to build an exhibition piece, a little bigger was better than a little too small. It’s well known, my American friends, you like big things with a lot of colors that lighten up, move, play music and glow in the dark! ;) Hesitating between many possible scales, I thought that one of the bigger options would probably be the way to go. You have that expression in English, what is it, again? Go big or go home. Right. I wasn’t about to go home.

Using as a reference a picture of me and some drawings of Rachnera, I tried in Photoshop to figure out THE perfect (big) scale for Rachnera’s body and legs. When I thought I had the correct scale, I sent my little Photoshop montage to Dutchprops. He’s the same 3D modeler I had hired to make my MKX Scorpion mask and I was very satisfied with his work. He already had the 3D scan of my body that he could use again to 3D model Rachnera’s body and legs, in proportion with my body, following the proportions on my reference Photoshop montage.

You can see more of Dutchprops’ work on his Instagram (@dutchprops) and Facebook:

www.facebook.com/dutchprops

If we had had a bigger budget, we could have sent the final 3D model to be cut in big styrene blocks by a 5 axis CNC. But both big styrene blocks and 5 axis CNC services would have been a pretty huge expense, so we went for a cheaper option, like we had done it for the robot. Cheaper, but way longer option. We did everyting by hand.

My friend used a software called 123D Make that allowed him to slice up the 3D model. We could then print the slices of the body and a reference shape for the legs. Each body slice was identified with a number. We glued the paper sheets on styrene boards and cut the slices with jigsaws. You can admire a big pile of styrene slices on the next pic.

Then we stacked and glued together all the styrene slices, following the numbers. To make sure that each slice would be centered on the previous one, my friend had placed on each slice to be printed not only a number, but also a mark identifying a center point. We pierced that point in each styrene slice and stacked the slices by sliding a wooden dowel in each slice’s hole. It may look like it would be obvious to stack the slices on top of each other like if there was only one way to do it. But when you put a smaller slice on top of a bigger one, the shape itself isn’t enough to show you where exactly to glue it. The position may not always be obvious and the holes were helpful. When we were building the robot, which had way more complicated shapes, this technique was essential to position each styrene slice. (Yes, we really built the robot with this technique of styrene slices. Yes, it took a lot of time. No, I wouldn’t do it again. Well, I did the spider. But I won’t do another robot.) You can see the wooden dowel on the next picture. It gives a better idea of the process.

Stacking 2 inches thick slices makes that you have those ‘steps’ around the shape. To get rid of the ‘steps’ we had to sand them down, and the shape of the spider’s body appeared.

NOTE: Before any of you ask, I’ll explain something one more time and I think I’m gonna copy/paste this at the beginning of each part of this blog. I’m not using a dust paper mask on the work in progress pics because wearing various masks irritates the skin of my face and gives me blemishes. The only fact of breathing in the humidity of my own breath in those masks makes my skin look bad. Then I can have a convention, a photoshoot or an interview and I have to wear more makeup to hide the blemishes, which isn’t good for my skin either. There are the masks for chemicals that I absolutely have to wear when I’m working with polyester resin or automotive paint. So when it comes to dust, I give my skin a break and I don’t wear a paper mask. I know it’s not the healthier choice, but most of models are usually not fiberglass technicians. I have to deal with two jobs that don’t go well together. So I make the choice, as sad as it is, not to wear paper masks to allow my skin to survive. But I do wear a mask for chemicals and vapors when I use polyester resin and automotive paint.

Then we cut 2 first MDF shapes following the paper guide of the slice extracted from the 3D model. We made 2 different leg shapes. A bigger/longer one for the 2 front and 2 back legs and a smaller/shorter one for the 4 middle legs.

We glued styrofoam on each side of a first MDF guide and sculpted the leg’s shapes following the guide. As I said before, there are more efficient ways to do big fiberglass structures like this. A 5 axis CNC would have sculpted the leg in a fraction of the time we took to sculpt it by hand. But we had our budget limitations, so we sculpted by hand. That being said, it was surprisingly fast to sculpt that first leg, which made my friend think that it wouldn’t be too bad to sculpt the 8 legs instead of sculpting a big one, a small one and make 2 molds. ‘Not making molds will save money’ he thought. ‘But it will take longer to sand and finish 8 legs made by hand. We should make molds’ I said. ‘Making molds wouldn’t be that expensive. It will be way faster. It will be worthed’ I added. But my friend disagreed. ‘No, no, let’s sculpt the 7 other legs already. It will be faster and we’ll soon be done.’ We have a proverb in French that says ‘Ce que femme veut, Dieu le veut’ which means ‘What a woman wants, God wants.’ This is never true with my friend. No woman (or man) will ever convince him to do something he disagrees with, so it would be more appropriated in his case to say ‘What my friend wants, God wants.’ He wanted to sculpt and cover with fiberglass 8 different legs. Well, we did. But we would soon realize (sorry, my friend) that we should have made molds.

Enough for today! Part 2 of my Rachnera making of blog coming soon!

In less than one month, Scorpion will be traveling to Illinois! I’m received as a cosplay guest for Count-I-Con in Grayslake on August 27th and 28th. I’ll have new stuff for you, collectible posters and a brand new sexy/cute product that hasn’t been announced yet! ;) See you there!

Visit the convention’s official website for more info:

www.counticon.com

Building my Monster Musume Rachnera cosplay was a challenge, an adventure, a learning experience and everything in between. I was more than excited to present it at Anime Expo at the beginning of July and even more excited when I got to meet Okayado, the manga artist and creator of Monster Musume, who came at the booth with his translator for an official picture. And most of all, you, my loyal supporters, have been following and enjoying the making of process online through the pics that I shared with you all along the way. I will never thank Ninja Division – Soda Pop Miniatures and Seven Seas Entertainment enough for having made that project possible.

I know that many of you still have questions about the techniques that my friend and I have used to build Rachnera. I’m working on a detailed blog that will regroup the explanations that I shared on my social medias with more information. Be patient, it will be worthed. And then I’ll go back to my Power Girl making of blog. Until then, you can find prints of Rachnera by clicking here. Hope you’ll enjoy. :)

Great news! I’ll be visiting Toronto for my birthday weekend! I’m a cosplay guest for Unplugged Expo on October 15th and 16th, at the Westin Harbour Castle Convention Center. See you there!

www.unpluggedexpo.com